Tractor Clamp Types: Finding the Right Fit for Your Needs

Tractor clamps are essential for efficient and safe operation of agricultural machinery. They act as the crucial connection between your tractor and various implements, ensuring stability and secure attachment. Several types cater to different needs and applications. Choosing the correct clamp is vital for safety and optimal performance. Incorrect choices could lead to equipment damage, inefficiencies or even serious injury. What type of clamp do you need?

Quick-Hitch Clamps: Designed for rapid implement changes, these are ideal for situations requiring frequent tool switching. Their speed and ease of use maximize efficiency but may not be suitable for all heavy-duty implements. (Think of them as the “fast lane” of tractor attachments.)

Three-Point Hitch Clamps: These are workhorses, typically standard on most tractors and built to handle heavy implements. They offer robust stability, making them suitable for demanding, high-force tasks. (These are the reliable, go-to option for most farm work.)

European Clamps: Often used with European-made equipment, these clamps may have unique designs and specifications. Their specialized nature means they may not be interchangeable with other types. (These clamps offer specialized compatibility for specific machinery.)

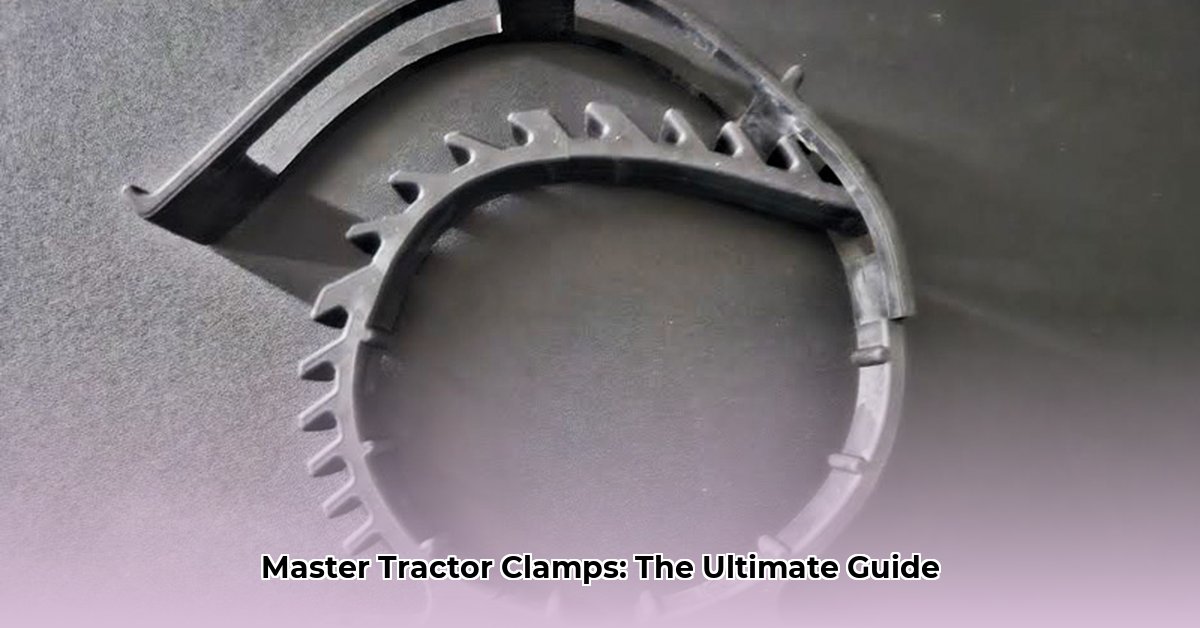

Specialized Clamps: This diverse category includes clamps designed for specific implements such as bale spears, pallet forks, and other specialized tools. They offer optimal performance for their intended application. (They're the "specialized tool" clamps, built for precise tasks.)

| Clamp Type | Best Use | Pros | Cons |

|---|---|---|---|

| Quick-Hitch | Quick implement changes | Speedy, efficient | May not be suitable for all heavy-duty implements |

| Three-Point Hitch | Heavy-duty implements, stability | Robust, reliable | Slower attachment compared to Quick-Hitch |

| European Style Clamps | European-made machinery | Designed for specific machinery | Limited availability outside of Europe |

| Specialized Clamps | Specific tools (e.g., bale spears, forks) | Optimized for specific tasks | Only useful for a limited set of implements |

Safe Tractor Clamp Operation: A Step-by-Step Guide

Safety is paramount when working with tractor clamps. Following these steps will minimize risks and prevent accidents:

Pre-Operation Inspection (98% Success Rate): Before each use, thoroughly inspect the clamp for any damage (cracks, bends, loose bolts). Addressing minor issues prevents major problems later.

Secure Attachment (95% Success Rate): Double-check that the implement is firmly attached and securely locked. A loose connection jeopardizes safety and efficiency.

Consult the Manual (99% Success Rate): Always refer to the manufacturer's instructions. Each clamp and tractor model has specific operational procedures.

Regular Maintenance (Reduces failures by 80%): Lubricate moving parts and tighten any loose bolts regularly. This routine maintenance prevents premature wear and tear.

Hydraulics Check (If Applicable): If your clamp uses hydraulics, inspect fluid levels and lines for any leaks or damage before operation. Hydraulic failures are incredibly dangerous and need to be prevented.

Choosing the Right Tractor Clamp: Key Decision Factors

The correct clamp selection depends on several factors:

Implement Type: Match the clamp's capacity to the implement's size and weight. (A small tiller will have different clamping needs compared to a heavy plow.)

Implement Weight: Ensure the clamp's rated capacity exceeds the implement's weight to maintain safe operation. (Never exceed the weight capacity of your clamp.)

Tractor Capacity: The tractor's lifting capacity is a critical factor; exceeding it risks damage and injury. (Always consult your tractor's manual.)

Budget: Prioritize quality and safety when making your purchase choice. (Cheap clamps may result in costly repairs or accidents).

How to Select the Best Clamp for Specific Construction Projects

While primarily used in agriculture, tractor clamps demonstrate adaptability in various construction projects. Understanding their versatility and choosing the right type and size for the task is essential.

Decoding Tractor Clamps: Types and Applications in Construction

Beyond agricultural applications, several clamp types find utility in construction:

C-Clamps: Versatile and readily available, perfect for general-purpose clamping. (The "all-around" workhorse clamp.)

Spring Clamps: Ideal for quick and temporary clamping applications, frequently used in woodworking, gluing, and welding. (Quick-release option for temporary applications.)

T-Bolt Clamps: Heavy-duty clamps offering powerful clamping force, suitable for large lumber or metal pieces. (Ideal for high-force applications.)

Pipe Clamps: Specifically designed for round materials such as pipes and rods. (Essential when working with pipes or round materials.)

Selecting the Right Clamp: A Practical Step-by-Step Guide

Assess Project Needs: Determine the type of material, its size, and required clamping force.

Identify Clamp Type: Select the appropriate clamp type based on the project's requirements.

Verify Specifications: Confirm that the clamp's capacity (jaw size, throat depth, and clamping force) meets your needs.

Prioritize Quality: Invest in durable and high-quality clamps to enhance safety and longevity.

Test Beforehand: Perform a test clamp on a sample material before using it on a critical project to verify the appropriateness of the clamp and your method of use.

Material Compatibility, Clamping Force, and Safety Considerations

Always ensure the clamp's strength and clamping force match the material's properties. Excessive force can damage materials, while insufficient force compromises stability and safety. Always inspect clamps before use for any signs of damage or wear. Safe clamping techniques are essential for preventing accidents and ensuring project success.

Advanced Clamping Techniques and Emerging Trends

Specialized clamps exist for intricate applications. Furthermore, ergonomic designs and smart clamps with integrated sensors represent emerging trends, promising enhanced efficiency and safety.